Insulating Glass Molecular Sieve

Insulating glass molecular sieve is the product to provide the insulating glass industry with the highest water capacity and lowest gas adsorption for solvent-free systems.

Technical Parameter

|

Model |

Insulating Glass Molecular Sieve |

||

|

Color |

Light gray |

||

|

Nominal pore diameter |

3 angstroms |

||

|

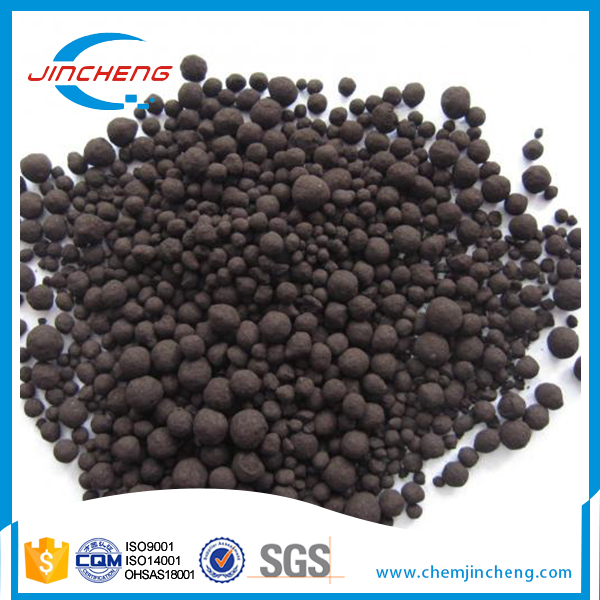

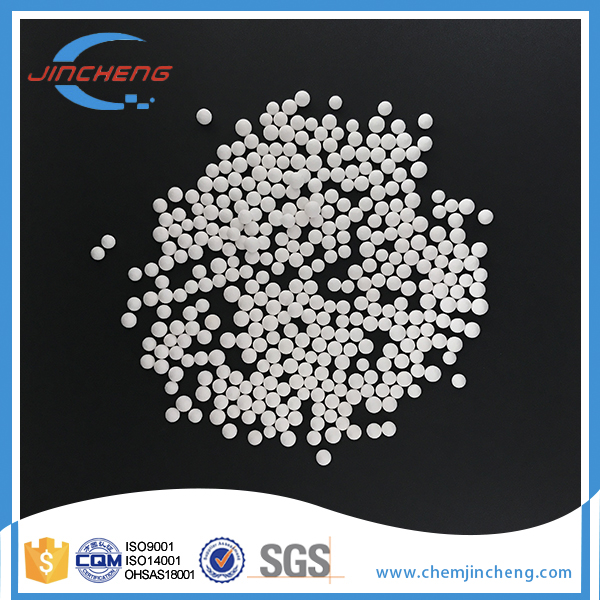

Shape |

Sphere |

||

|

Diameter (mm) |

0.5-0.8 |

1.0-1.5 |

1.5-2.0 |

|

Bulk density (g/ml) |

0.74-0.80 |

0.72-0.78 |

0.72-0.78 |

|

Static water absorption (%) |

>20.0 |

>20.0 |

>20.0 |

|

Crushing strength (N) |

>5 |

>15 |

>20 |

|

Dust (Turbidity meter) ppm |

<30 |

<30 |

<30 |

|

Delta T (10 g /10ml) degree C |

>38 |

>38 |

>38 |

|

Equilibrium N2 capacity (% ) |

<0.2 |

<0.2 |

<0.2 |

|

Dew point degree C |

<-73 |

<-73 |

<-73 |

|

Size ratio (%) |

>98.0 |

>98.0 |

>98.0 |

|

Water content (%) |

<1 |

<1 |

<1 |

|

Typical Chemical Formula |

0.45K2O . 0.55Na2O . Al2O3 .

2SiO2 . 4.5H2O |

||

|

Typical Application |

For insulated glass adsorption at the same time insulating glass of water and organic residues, so that the insulating glass, even in very low temperatures remained bright and clean and transparent, at the same time be able to reduce the insulating glass full season as a result of the temperature difference between day and night and are subject to great changes both within and outside the powerful Pressure on the poor, solve common insulating glass desiccant easy to make hollow glass or expansion and contraction caused by broken distort the issue, fully extend the life of insulating glass. |

||

|

Package : |

Carton box; Carton drum; Steel drum |

||

|

MOQ: |

1 Metric Ton |

||

|

Payment Terms: |

T/T; L/C; PayPal; West Union |

||

|

Warranty: |

a) By National Standard GBT 10504-2008 |

||

|

b) Offer lifetime consultation on problems occurred |

|||

|

Container |

20GP |

40GP |

Sample order |

|

Quantity |

12MT |

24MT |

< 5kg |

|

Delivery Time |

3 days |

5 days |

Stock available |

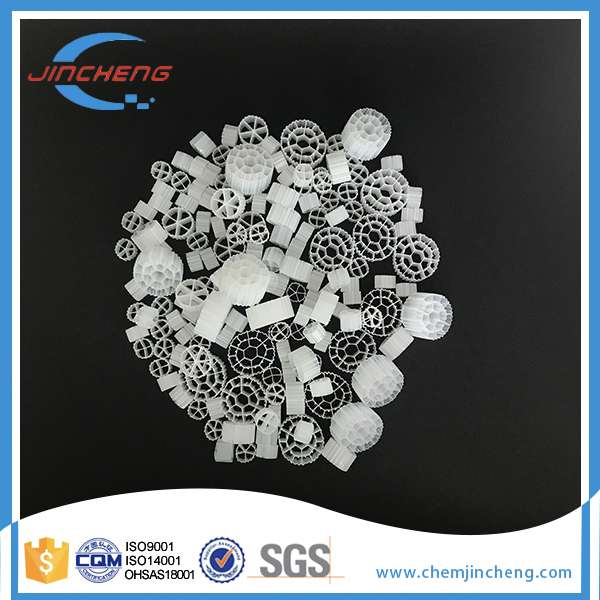

Feature

Very Selective Adsorption

Insulating glass molecular sieve has been designed as a high water capacity

adsorbent with the lowest capacity for air or other gases. The highly selective

pore structure of assures excellent water dew point protection while eliminating

the co-adsorption of gases in the sealed air space.

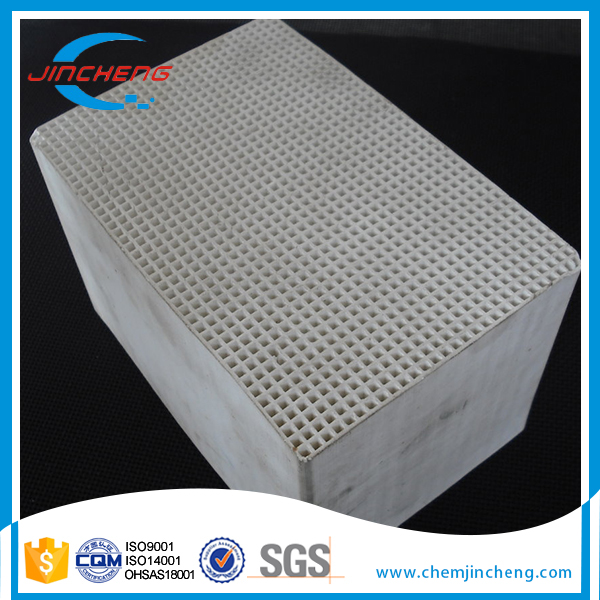

Low Deflection

Because insulating glass molecular sieve minimizes pick up of other gases, it

reduces adsorbent contribution unit deflection and stress under severe climatic

conditions.

Economy and Performance

It increases gas-filled nit production rates since units can be sealed

immediately after filling. In addition, the use of insulating glass molecular

sieve maintains unit sound and heating insulation values by minimizing the

adsorption of gases from the sealed space.

Homogeneous and

Non-Separating

Unlike blends of two different desiccants that separate because of different

component densities,insulating glass molecular sieve is homogeneous and

uniform. Each bead is like every other. There's no need to worry about

unit-to-unit variation, which can occur with blends.

Residual Moisture

Insulating glass molecular sieve is supplied as a fully activated Insulating

Glass Adsorbent, ready for use in spacer filling operations.