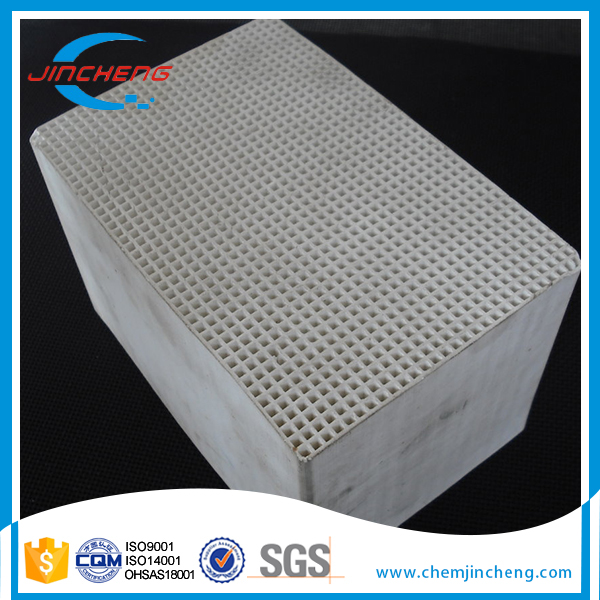

Honeycomb Ceramic

Cordierite is a magnesium alumina silicate material, which has very low linear expansion, low coefficient of thermal expansion and excellent resistance to thermal shock. Cordierite also offers an excellent range of mechanical strength, porosity criteria, and excels in cost-effective extruded and dry-pressed forms.

Cordierite Honeycomb Monoliths are divided into two types: porous type and compact type.

Chemical composition

|

SiO2 |

Al2O3 |

MgO |

Fe2O3 |

Na2O |

K2O+CaO |

|

48-50% |

37-39% |

7-9% |

<1% |

<1% |

<2% |

Physical properties

|

Index |

Value |

|

Gross density(g/cm3) |

2.22-2.45 |

|

Average linear expansion(20-1000degree C) (10-6/k-1) |

<3 |

|

Specific heat capacity(KJ/Kg) |

850-950 |

|

Temperature cycle resistance(K) |

250 |

|

Max operation Temp.(degree C) |

1300 |

|

Acid resistance(%) |

>98 |

|

Water absorption(Wt%) |

<3 |

|

Open porosity(%) |

<3 |

|

Heat conductivity(W/mk) |

1.5-2.5 |

|

Mean heat storage capacity(Kwh/m3k) |

0.252 |

Technical data

|

Spec. |

Quantity of channels |

Wall thickness (mm) |

Surface area (m2/m3) |

Free volume (%) |

Average weight (min.) (kg/m3) |

|

150*150*300 |

60*60 |

0.5 |

1278 |

64 |

730 |

|

150*150*300 |

50*50 |

0.7 |

1050 |

58 |

814 |

|

150*150*300 |

40*40 |

0.7 |

883 |

65 |

720 |

|

150*150*300 |

33*33 |

1 |

700 |

59 |

737 |

|

150*150*300 |

25*25 |

1 |

573 |

68 |

580 |

Thermal efficiency

|

Velocity (M/min) |

Thermal efficiency |

Assumptions |

||

|

50*50 |

33*33 |

25*25 |

||

|

60 |

95.40% |

92.40% |

91.20% |

|

|

75 |

94.60% |

91.00% |

89.40% |

|

|

90 |

93.90% |

89.60% |

87.60% |

|

|

105 |

93.20% |

88.40% |

85.70% |

|

|

120 |

92.60% |

87.20% |

83.80% |

|

|

135 |

92.00% |

86.00% |

82.00% |

|

Application

Used in heat storing HTAC to exchange gas and store heat

Heat storing honeycomb carrier is also called high temperature incendiary heat storing carrier. It is the key and core part of heat storing HTAC. It has been widely used to all kinds of pushing-steel heating furnace, stepping heating furnace, heat treatment furnace, forging furnace, dissolving furnace, steel wrapping/middle wrapping baking apparatus, soaking pit, radiation tap incendiary apparatus, covering furnace, high temperature hot-blast stove in metallurgical machine building and all kinds of ceramic cellar stove, glass cellar stove in building materials, and all kinds of tap heating stove, splitting stove, other industrial stove cellar, too.

Heat storing HTAC is a new concept incendiary technology. It combines organically recover smoking gas and remaining heat with efficiently burning and reducing discharging Nox, so it can get the double aims of saving energy ultimately and reducing discharging Nox ultimately. The technology characters as follow:

Smoking gas and remaining heat recovering device is adopted to replace and exchange smoking gas, air and coal gas, so while they pass the heat storing, they can recover ultimately physical heat in high temperature smoking gas and save energy (normally 10%~70%)and improve the efficiency of heat apparatus, and reduce replacing of CO2 (10%~70%).

By expanding the area of flame burning (almost to the edge of stove) by poor oxygen burning, it can make the temperature in stove even, so Nox in smoking gas reduced above 40%.

Because the average temperature in stove is raised and heat conduction is improved, heat apparatus in the same size can improve output above 20% and reduce the cost of apparatus.

Low calorific value fuel can get high stove temperature with high temperature preheats gas or high temperature preheats gas, so it has expanded the low calorific value fuel use range.

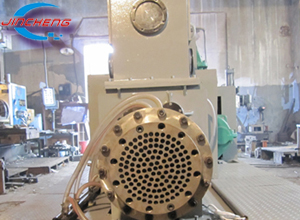

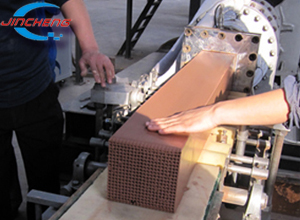

Process production: